Competition in various corporations has always been tough, that’s why they have to be transformed in all aspects of business operations. Since the rise in technology is quite fast, then entrepreneurs mustn’t take a break, but instead utilize these innovations to cope. In this way, businesses can be more profitable and acquire investors to protect their companies from distinguished competitors.

Let’s take a look at enumerable manufacturing corporations in Germany, how can they meet the demands of their clients when production is slow? Machinery must be maintained and upgraded for maximum performance, especially when orders are rapidly growing. Therefore, they’ll have to be digitally prepared and equipped by integrating various advancements in technologies.

That’s what you’d do, especially when you belong to the manufacturing industry, where you’ll be requiring the fastest methods in terms of producing goods. So if your demands are high, then services, such as plusmanufact.de would be of great help. This offers 3D printing in Germany, so how do you think can it benefit your business?

Additive Manufacturing

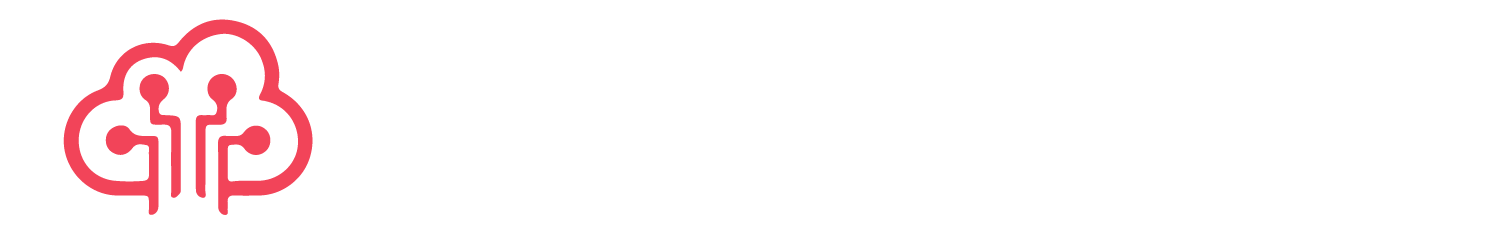

This pertains to 3D printing, which is a manufacturing and industrial technology used globally nowadays. It involves a process where breaking down of layered materials is performed to produce products from three-dimensional models. I guess, it can be an effective tool in highly customized and low-capacity industries.

You should know that this doesn’t only work in one application, but helpful to manufacturing companies. Different engineering approaches are reformed so that they can adapt to various settings. Therefore, if you’d like to implement this system, then you’ll be dealing with suitable materials and mechanisms.

Of course, we have professionals who’ll assist you in defining the precisemethod for your specific requirements. You’ll must select from various objects, such as liquid, power-based, and filament. With these, you can print through selective laser sintering, fused deposition modeling, stereolithography, binder jetting, etc.

Simple Designing Process

Designing involve CAD applications in some parts but you’ll have more freedom with the 3D. With advanced technologies, drafting angles are easier to manage since you have accessible tools. What makes it costly is how complicated the design would be and the materials used – visit https://redshift.autodesk.com/articles/what-materials-are-used-in-3d-printing for examples.

Traditional printings are even shifting to three-dimensional because this can be used in numerous applications. Thus, ensuring the manufacturers complete their models since limitations are minimized.

Simplified Multifaceted Geometries

In parametric designs, certain software is used to manufacture them. It’s an ideal tool for shapes because features and dimensions are given. These components are accurately drawn and must fit, so CAD isn’t used in this case.

But this is possible with 3D since it can manage even the complexity of mesh. Manipulating and modifying geometries would be easier. Therefore, you can meet the required mass for specific requests.

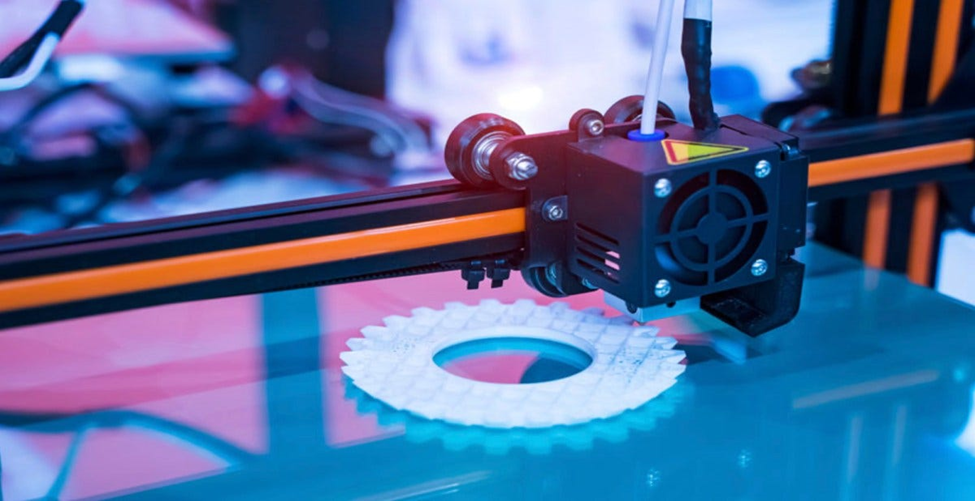

SwiftPrototyping

When manufacturers are developing products, they often require prototypes for testing. Imagine how much time you’ll consume with traditional methods. Fortunately, prototyping speed is now resolved because the experts can make copies rapidly.

Due to these prototypes, developers have more chances of producing better innovative products. In the developing stage, they can already determine what must be modified. Therefore, the models can be changed immediately before submitting to the next phase.

Traditionally, developing projects may take a year but it’s now reduced to a maximum of 5 months. Through advanced methods, the timeframe for this whole process is accelerated. Therefore, there’ll be more time to finalize the design and check for improvements – go here to learn more.

Just-in-time Manufacturing

If your business manufactures various parts and delivers them to different industrial companies, then you’ll surely want to have a clean inventory. This means that there shouldn’t be delays and cancellations of orders. Anyway, this won’t happen if you can obtain the quantity your clients are demanding on time.

You have clients who prefer to order directly from suppliers. With this, they don’t need to wait for these items to reach the warehouse because that process will be longer. Luckily, with 3D printing, all means of delivery are possible due to its flexible features.

I supposed you have a database, where all available stocks are listed. You can simply access this to figure out how many more items you need to process. Thus, nothing can interrupt client-supplier relationships.

Shorter AssemblingIntervals

With these advanced technologies involved, expect parts to be formed faster. Even if you have to combine several prototypes, the time it would take when assembling is shortened. That’s because you have machines working on them.

In cases where manual labor is needed, while the other parts are machine-operated, production time can be shorter. The templates and molders are already there, so all you need is to print out the prototype. No matter how complex it is when attaching them, the situation can be handled smoothly.

Flexible Solutions with standard, engineering, and high-performance polymers

Polymers, such as PVC and PET are the commonly used plastic material in industrial businesses. It’s designed with diverse characteristics or properties, making it ideal for various products. In mass production, they can be printed out with ABS or Acrylonitrile Butadiene Styrene for instance.

Engineering plastic materials to produce machine components or parts is also possible. However, polymers are often combined with other substances to enhance their properties. Construction and automotive industries will surely have access to the products they can do.

But for higher quality performances, more stringent resources are required. Polyether ether ketone and polyetherimide can be fulfilling. Motorsport and aerospace sectors will greatly benefit from this.

Internalized Production

Due to various manufacturing costs of products, reducing the company budget is often discussed. This is always a concern in every business because they need to maintain cash flow and must be profitable. Internalizing their production is one of their resolutions.

Therefore, aside from dealing with 3D printing providers, they can also purchase such equipment. However, that’s when there’s a sufficient budget for this because it would be expensive to get one. Overall, this will greatly benefit the manufacturer because they can make prototypes faster with larger quantities.