Two gases contained in ordinary water can create serious damage to metal when steam is created. The first chemical is oxygen. When released through the steam creation process, oxygen will attach to metal parts and begin an oxidation process. Unless treated, oxidation will quickly rust metal components of any machine. The other chemical that can do damage is carbon dioxide. As it dissolves in the steam production process, the dissolved byproduct is carbonic acid. This acid is particularly harmful to metal parts.

Since the primary purpose of a steam boiler is to create steam, it is inevitably vulnerable to both oxidation and carbonic acid. Therefore, manufacturers were required to develop a method to remove these two chemical compounds from water before entering the boiler. The tried and true method for doing so is referred to as a deaerator chamber.

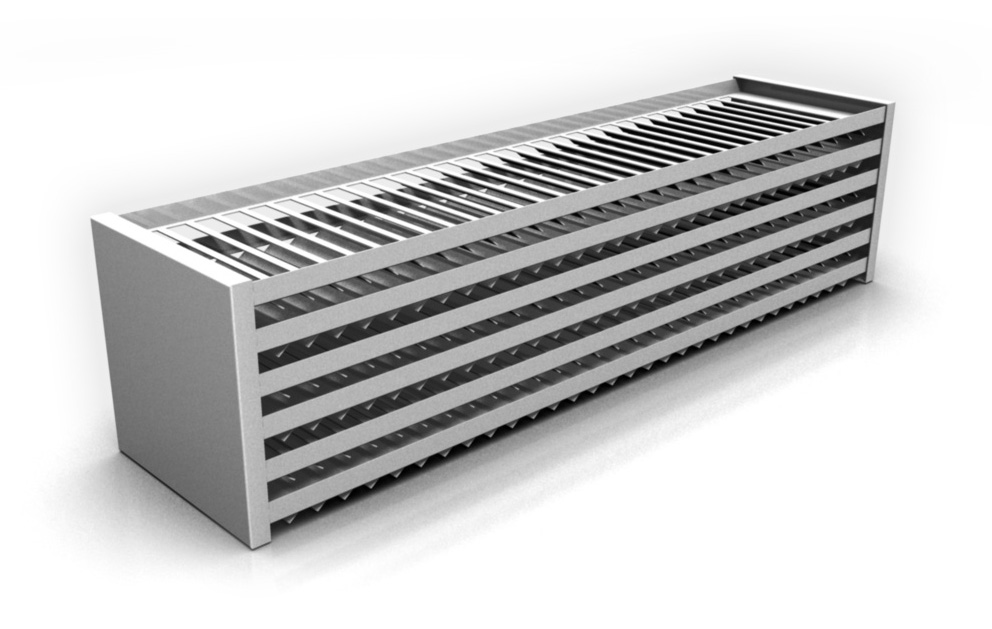

A number of different methods are used, but the tray deaerator remains a popular and efficient system.

The process begins by running feed water into the deaeration chamber. Feed water can be from a municipal water supply, a well, reservoir or recirculation system. The feed water then runs through a series of perforated metal trays. As is flows through the trays, low pressure steam is forced upward to strip the feed water of oxygen and carbon dioxide. These chemicals then are vented to the outside through vent located at the top of the deaeration chamber. The deaerated feed water is then fed into the boiler system.

Deaerator trays constructed of stainless steel normally have a longer useful life than those of regular sheet metal or other substances. In either case, ordinary maintenance of the dearator chamber should include inspection of chamber walls, spray valves and system trays. A worn or faulty tray will not work efficiently and will allow dissolved gases to enter the boiler system. This will put the boiler components at risk. Fortunately, firms are available that manufacture and sell a wide range of replacement trays. Replacement parts can be purchased and installed quickly, avoiding a great deal of down time for the boiler system.